| AMT Backup | |

|---|---|

| Type | Semi-automatic pistol |

| Place of origin | United States |

| Production history | |

| Designed | 1978 |

| Manufacturer | AMT Galena Industries High Standard Manufacturing |

| Specifications | |

| Mass | 18 oz (0.51 kg) |

| Length | 5 inches (13 cm) |

| Cartridge | .22 LR .380 ACP .38 Super 9×19mm .357 SIG .40 S&W .400 Corbon .45 ACP |

| Feed system | 8 rounds (.22 LR) 6 rounds (.38 Super, 9mm, .357 SIG) 5 rounds (.380 ACP, .40 S&W, .400 Corbon, .45 ACP) |

| Sights | Fixed |

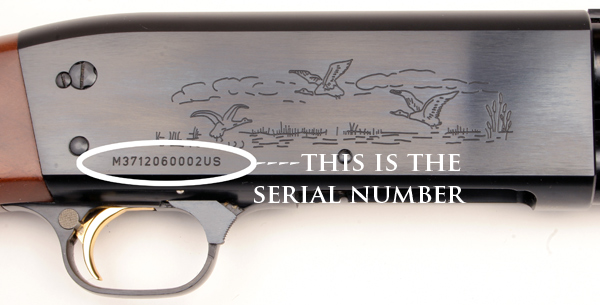

I would say that your grandfather had a pretty good relationship with AMT or contacted them to commission a special gun for himself. That inscription 'ELK45' is the serial number. Pretty cool and it's the first AMT I have seen with a custom serial #. Nice touch that the grips match too. Since we are examining Andrew’s pistol that is an AMT Automag II.22 Rimfire Magnum, and the original AMT Automag II was produced from 1987 – 2001, we could date his as likely being a true-blue AMT. Also, his pistol does have Irwindale, CA stamped on the slide as a dead giveaway (but it can be fun to sleuth for our facts as well). Ehlers Pistols 4 th & 5 th Model Holster or Texas Paterson No.5 Model 1849 Pocket Model 1849 Pocket London Model 1855 Sidehammer.28 Caliber Model 1855 Sidehammer.31 Caliber Model 1862 Police Pocket Pistol of Navy Caliber New House.38,.41 &.32 New Line.22 Pocket New Line.30 Pocket New Line.32 Pocket New Line.38 Pocket.

AMT Hardballer Serial Number I have looked through the 40+ threads on this subject, have found 3 closed threads, and decided to open a new one. I have owned a used AMT Hardballer since 1992, bought from a private seller at a gun show (a security guard who, after the purchase, informed me that it was a 'dangerous, defective gun') for $150.

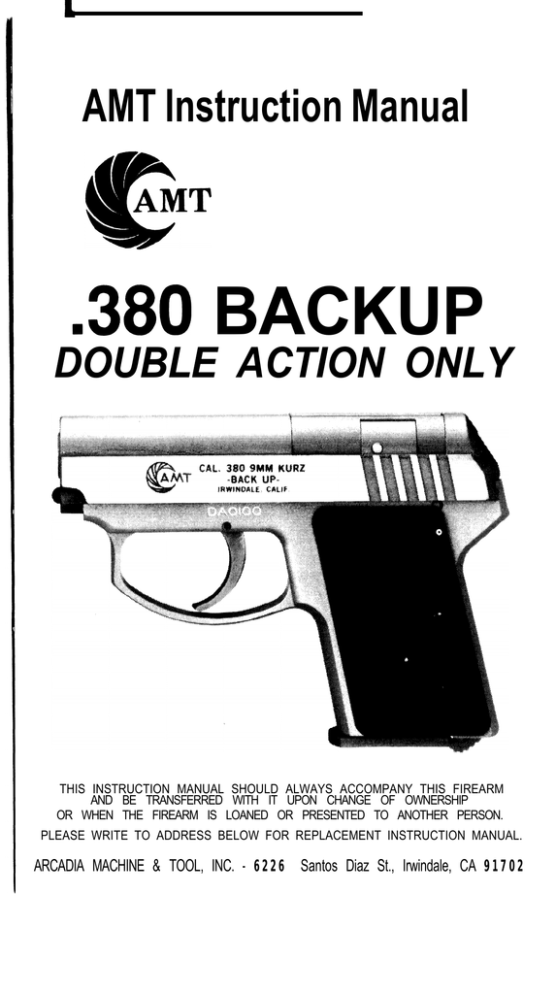

The AMT Backup is a small semi-automatic pistol. It was first manufactured by the Ordnance Manufacturing Corporation (OMC) of El Monte, CA. The first guns made in .380 ACP by OMC are known as the OMC Backup. OMC produced a short run of these pistols before the tooling was purchased by Arcadia Machine & Tool, who took over production. AMT .380 ACP Backup pistols were made by AMT in El Monte, Covina California, and Irwindale, CA.

The original AMT Backup was produced with a single-action only (SAO) trigger mechanism, while the later 'Small Frame' and 'Large Frame' Backup used a double-action-only (DAO) mechanism. These pistols were manufactured by AMT and later Galena Industries (until November 2001).[1] SAO pistols were made with a manual safety, while DAO guns relied on their heavy trigger pull for safe handling.

The AMT Backup was available in a wide range of calibers: .22 LR, .380 ACP, .38 Super, 9×19mm, .357 SIG, .40 S&W, .400 Corbon and .45 ACP have all been offered.

The pistol's marketing slogan was 'the smallest, most powerful' backup weapon available (referring to the 45 ACP version).[1]

The AMT Backup line of handguns were being marketed by High Standard Manufacturing.[2]

Sources[edit]

- ^ abShideler, Dan (2010). Gun Digest 2011. Iola, Wisconsin: Krause Publications. p. 114. ISBN978-1-4402-1561-2.

- ^http://www.highstandard.com/

External links[edit]

This article first appeared on the AMT Guns forum on 13 November 2013.

Amt Pistol Serial Numbers Lookup

Auto Mag Collectables (Guide)

By Bruce Stark

July 2010’

Introduction

Most Auto Mag enthusiasts soon become accessory collectors whether they know it or not. Buy some ammo or a holster and you are on your way. Some Auto Mags were marketed with the promise of an accessory package to be included with the sale of the gun.

This article is intended to highlight the many different directions this sub-category of Auto Mag collecting can take. It is not intended to be a complete list of all Auto Mag collectables but is more of a guide. Because of the limited number of Auto Mags and accessories made, just about anything with the Auto Mag name on it has become sought after by the collector, paintball guns and automobile magazines excepted.

Collecting Auto Mag accessories can be very rewarding. It is educational, helps complete a gun advertised with accessories and eventually builds an inventory of items that can be used for sale or trade.

A few unique items are listed at the end of this work that wouldn’t fit into any particular category.

1) Automag and Auto Mag named guns

After Auto Mag Corp. went bankrupt in 1972, Harry Sanford went on to develop more semi-auto stainless steel handguns in out-of-the-ordinary calibers. The name Auto Mag was changed to Automag for these Browning based designs. There was an Automag II (.22WMR), an Automag III (.30 Carbine or 9 mm Magnum), an Automag IV (.45 Win Mag or 10 mm Magnum) and an Automag V (.50 Action Express). Harry Sanford also made many other handguns and rifles that didn’t have the Automag or Auto Mag name.

After the movie Sudden Impact came out, there was a desire by collectors to obtain an 8.5” fully ribbed .44AMP barrel like the one Harry Callahan used. Unfortunately this was a custom barrel and no production inventory ever existed. Brian Maynard, the AMT Service manager at the time, designed the Baby Auto Mag using an AMT Lightning pistol as its base. It was only a 22LR but it captured the look of the movie gun. As usual Harry reserved one hundred serial numbers for his own personal assignment. These guns got special markings on the receiver. The gun could be marked “Make My Day” or “Feel Lucky Punk” or both. Baby Auto Mags came in a wooden box which included a sticker saying “One of 1000.”

2) Auto Mag parts

Some shooters want to have spare parts on hand in case there is parts breakage or loss in the field. At least having some spare parts at home will allow one to get the disabled gun up and running again. Spare magazines are a must for most shooters. Spare barrels can allow one to change calibers, barrel lengths and maybe add a scope to the situation if needed. Like most things there are many different versions of replacement parts from different production runs and it’s easy to start collecting them.

This sub-category of collecting can be approached from several directions. A complete set of spare parts for one particular gun is one way. Collecting the most easily damaged parts is another way to go. Some parts are better than others so maybe collecting upgraded parts is another path to follow. One could just collect every version of every part for the gun including XP and prototype parts.

Starting with part number one, the Barrel, there are Pasadena, TDE North Hollywood, El Monte, High Standard, Lee Jurras, Kent Lomont, OMC, AMT, AMC, AM Irwindale and AM Sturgis SD. There are also the unmarked Barbasiewicz barrels. There are barrels in lengths from 4.5” to 16.5” ribbed and un-ribbed. Some barrels are polished or engraved or in field grade stainless. There are electro-etched markings, engraved markings and the rare roll engraved markings. There are at least 8 different calibers and some barrels are scoped or mag-na-ported. There are bull barrels and tapered and un-tapered barrels. Kent Lomont even made some octagon barrels. The combinations are endless.

Part number 6, the Rear Sight Platform, was improved during the El Monte days with two more lands to prevent lateral movement. Some were black for anti reflection.

Part number 10, the Rear Sight Blade, went through many changes. The Pasadena blade had an outline cut around the notch. The anti-reflection lines were later eliminated in favor of making the blade black.

Part number 12, the Grip Screw, was also made in carbon steel so they could be blackened. It is an 8-48 button head Allen screw.

Parts number 13 and 14, the Grips, are a popular collectible. The Pasadena fully checkered grip was changed to the TDE partially checkered grip. Some people had complained that the Pasadena grips would tear up the webbing in their hand. TDE North Hollywood grips were hand cast and hold up well. The El Monte grips were injection molded with cheap model plastic and usually break right after the first shot. This created an instant market for aftermarket grips. Don Mitchell, the then CEO of High Standard, insisted that the High Standard Auto Mags be equipped with the North Hollywood grips. Don Mitchell told the author, “I held Harry to a higher standard.” Lee Jurras used grips made by Clint Teeters on most of his custom guns. They were a laminate of different hard woods that look real nice and hold up well. The factory had another run of the partially checkered grips made, but this time a better plastic was used and they don’t break. The Harry Sanford Signature Series guns have wooden grips.

Part number 22, the Bolt, has seen many changes. The Pasadena and North Hollywood bolts are the same. The El Monte bolt had one major change with the new half moon cut that receives the safety tappet. There is a transition bolt between the two that Larry Grossman made a few of. The “B” model guns received a solid bolt that was made of carbon steel. Again there was a transition bolt. It was a stainless version of the solid bolt that was never used. At one time the factory tried casting the bolt but it was unsuccessful. The bolt will break, but the damage is usually a result of loose recoil rods or hot loads.

Part number 28, the Extractor, can easily be broken and is a spare part one really should have on hand.

Part number 31, the Safety Plate Spacer, came in five sizes.

Part number 32, the Safety Plate, can get lost if the number 30, Retaining Ring, comes off.

Part number 37, the Trigger Bar Spring, was originally a heavy spring that worked as designed. Sometime in the El Monte days a new weaker spring was used that had to be epoxied into the frame to keep it from coming off. Bob Beal came up with an idea of drilling a keeper hole in the frame to secure the spring. This idea was later incorporated into the gun’s design.

Part number 45, the Safety Lever, uses part number 30, Retaining Ring, to secure it to the gun. Some, including Lee Jurras, have drilled out and threaded the Safety Lever to install a small screw to hold things together. This is a far superior approach as the Retaining Ring will sometimes just fly off.

A collection could be made of unfinished parts such as rough castings of the frame or cocking piece, unfinished bolts and sheet metal stampings. These types of items were routinely handed out as souvenirs during factory tours.

3) Ammunition

Amt Pistol Serial Numbers Search

Brass

As of this writing there have only been five different head-stamps on factory-made Auto Mag brass. One can fabricate one’s own Auto Mag brass from rifle cases but here we will discuss brass that has an Auto Mag head-stamp.

First there was CDM in Mexico that provided loaded ammo and un-primed brass in .44AMP. CDM used 210 grain and 240 grain jacketed hollow point bullets that were designed by the Auto Mag factory. CDM ammo was generally found to be underpowered and inconsistent. These problems are probably a result of dirty powder. If one fires off a round of CDM ammo, a large amount of unburned powder is usually found to be fouling the gun.

Next, Norma in Sweden offered loaded .44AMP ammo and unprimed brass. Norma used a 240 grain jacketed hollow point bullet of their own design. Norma ammo is considered hot but it is very consistent.

Starline brass, in Sedalia, Missouri makes .44AMP Auto Mag brass and also offers it with nickel plating. Dakota Ammo, Inc & Glaser, LLC in Sturgis, South Dakota have loaded this .44AMP Starline brass and sell it under the Cor-Bon name. Some find it a little on the hot side but it is consistent. At one time “Old Western Scrounger” offered their Cowboy load using Starline 44 Auto Mag brass.

Quality Cartridge in Hollywood, Maryland has made a limited quantity of Auto Mag brass head-stamped, 41 AUTOMAG and 357 AUTOMAG.

Ammunition

Several different companies and individuals have loaded and sold Auto Mag ammunition. Some have used Auto Mag head-stamped brass and some have used brass made from rifle cases. CDM and Norma ammo can be determined to be factory loaded by verifying the presence of their unique bullets. I don’t know of Norma or CDM selling these bullets to the public. This is not so for other loaded ammo as off the shelf bullets were used in the first loading. A reloader could use the same bullets to create a load that looks like the first loading. You could have a box of reloads. An unbroken seal on a box of ammo is the only way to confirm that the brass has not been reloaded. Lee Jurras of Super Vel used his own unique jacketed bullets and he also sold the bullets separately.

The Auto Mag factory made a small run of ammo that they sold for a while in the early Pasadena days. They made their own brass by extruding cut-to-length rifle cases to .44AMP dimensions. Bob Beal of Beal’s Bullets in Pottstown, Pennsylvania started supplying Auto Mag ammunition including his “Break-In” loads in mid 1971. Bob’s brochure was included with most Pasadena Auto Mags. CDM ammo and brass was available by late 1971 and Norma started delivery of ammo and brass around the time of the Pasadena bankruptcy in 1972.

Lee Jurras loaded and sold Auto Mag ammunition under his name and the Super Vel name. Kent Lomont in Indiana, Sandia in New Mexico and Western Reloading Inc. in Santa Ana, California also offered Auto Mag ammo. The Western Reloading ammo was made by a Wyatt Lomont. Wyatt used a drill bit to inside size the cases instead of a reamer. This was the worst ammo ever made for the gun. The author asked Kent Lomont if he was aware of Wyatt Lomont’s ammunition. Kent said yes he was and he had in fact once talked to Wyatt Lomont. Kent said he asked Wyatt to change his last name to Earp.

4) Dies

Before the Auto Mag went into production, RCBS had already made dies for the .44AMP, .357AMP and 300 Auto Mag. When the gun went into production, RCBS was ready with a case forming set and a reloading set of dies for the .44AMP. RCBS usually puts a date on at least one die in a set using just two numbers. The “advanced” collector would want a 71 or a 72 marked set of dies to go with his Pasadena gun.

RCBS made die sets for Kent Lomont’s wildcat Auto Mag cartridges. The .30LMP (Lomont Magnum Pistol), .25LMP and .22LMP dies are the rarest and hardest to find.

The .44AMP case forming set uses a reamer to create the correct inside dimension for the .44 bullet inside a piece of cut-to-length rifle brass. To create .41JMP or .357AMP brass, most people simply neck down the completed .44AMP case to .41JMP or .357AMP using the appropriate sizing dies. RCBS also made .41JMP and .357AMP case form sets. These sets first require one to neck down a piece of cut-to-length rifle brass and then use the supplied reamer to ream only the neck to the .41 or .357 bullet’s dimensions. The thinking is that only the neck is reamed, requiring less reaming, and you would end up with a stronger case. There was one case forming set made for the .300AMP. It had a different shoulder angle than the later made Lomont .30LMP.

A taper crimp die was included in the RCBS .44AMP and .41JMP reloading sets. The crimp keeps the bullet from moving in the case before it is fired. RCBS also made a taper crimp die for the .357AMP that was sold separately. It has been argued that since the .357AMP seats on the shoulder that a roll crimp would have been more appropriate.

Hollywood Engineering of Sun Valley, California, maker of the Hollywood reloading presses also make dies. The owner, Joe Mueller, saw a need for a carbide .44AMP die and made some on a limited basis. He made one in .357AMP but complained that it required two carbide inserts and was a pain to make. RCBS now offers carbide dies for the Auto Mag.

Pacific made a reloading set of dies for the .44AMP named “Pacific Durachrome. “

Eagle made both a case form and a reloading set for the .44AMP.

Bair Company out of Lincoln Nebraska also made reloading dies for the .44AMP

5) Holsters

Holsters are sort of an open ended collectable. Most custom leather shops can make a one off holster for an Auto Mag and many have. Production runs were made by a few manufacturers that we will cover here.

Early on a few guys from the factory had Alfonso Pineda of Alfonso’s Holster Shop in North Hollywood, California make up custom holsters for them. Alfonso worked with Arvo Ojala before starting his own shop where he developed his Hollywood Fast Draw Holster. Alfonso’s Holster Shop supplied the studios with Western rigs, many of which were made for Hollywood celebrities such as John Wayne, Gary Cooper and Sammy Davis Jr. His son is now running the shop in Burbank, California.

Safariland was located in Monrovia, California and Harry soon had them making holsters for the Auto Mag. Early ads for the Auto Mag said, “Strap a rifle on your hip.” Safariland started their ad campaign for Auto Mag holsters by saying, “Now! You can ‘carry a rifle on your hip.’” Safariland also made shoulder holsters and magazine pouches for the Auto Mag. Safariland made at least one custom holster that accommodated the Willis Scope Mount. Some say that early on Harry got Safariland to invest in Auto Mag Corp. Safariland is now located in Ontario, California.

Lee Jurras offered holsters that had his lion head logo on them. He had them made by Safariland. On the reverse side of Lee’s holsters and magazine pouches it is stamped “L.E. JURRAS & ASSOC. USA.” Lee also had a custom holster made for the Backpacker Auto Mag for collector Mike Mace. It was made by The Hide Shop in Ruidoso, New Mexico.

Bianchi made some beautiful holsters for the Auto Mag. They are located in Temecula, California and are now part of Safariland. Their cavalry style flap holster model is one of the most sought after holsters by collectors. Their model 116 holster with the built in magazine pouch came in two styles. One is for the 6.5” barreled gun and the other is for the 8.5” barreled gun. I am told that the Bianchi “X-15 Large” is a very popular , current production, holster for the Auto mag.

Roy’s Original Pancake Holsters of Magnolia, Arkansas made a model for the Auto Mag.

Model Gun Corp. (MGC) of Tokyo, Japan made a simple leather holster for their toy Auto Mags that works quite well with the real gun.

Today, Frontier Leather Works in Strasburg, Pennsylvania offer a custom line of Auto Mag holsters, magazine pouches and shoulder holster rigs. They will also build a custom holster of your own design. Frontier can laser cut the Auto Mag logo onto the leather.

6) Gun Cases

The black plastic case that was provided with most Auto Mags was ill suited for this application. The plastic handle would break or the latch would unlatch and cause the gun to crash to the ground. In later years it was discovered that the foam in the case eventually turned into a goo that would etch pits into the stainless steel.

William Chizar, the engraver, had two cases made for his two personal engraved guns but the engraved guns he sent to the factory had no cases. There was a request for cases so the factory ordered them from custom case maker Dan Herrera of Walnut, California. Mr. Herrera was again called upon to make cases for the Bicentennial guns and was regularly recommended by the factory to customers requesting custom cases. The author paid Mr. Herrera to watch the movie Malone so he could check out the case Burt Reynolds used for his Auto Mag. Mr. Herrera then made ten copies of the case. When the Baby Auto Mags were made Mr. Herrera agreed to make 1000 cases for the factory. He put off making the cases as long as he could. He said he waited outside a Mexican restaurant until they closed and hired all the dishwashers and waiters to work through the night to help him complete the cases. He said he had quoted the factory a bargain basement price on the cases and they sure look like it.

Lee Jurras supplied a Gun Ho case with each of his Custom Model 100’s. Most had a gold interior but some had zebra or tiger striped cloth inside. Mr. Jurras supplied his Custom Model 200 “International” with a “Custom compartmented Belting leather attaché-type case.” The owner’s initials were burned into the case and the combination lock was set to his birth date.

Walt Jones, while working at the Galena Irwindale factory, found someone to make some fine cases for the Harry Sanford Signature Series Guns. The Pasadena logo was laser cut into the lid of the box.

7) Factory Tools

Factory tools and fixtures are out there but are hard to find.

Ed O’Neil was Harry Sanford’s personal custom gunsmith. Ed developed a following of collectors who bought what Ed called “The rarest of the rare.” Harry used Ed to get quick cash in times of need. Harry would sell Ed bags of Auto Mag parts and sometimes factory tools and paperwork that were no longer being used. Harry sold the aluminum masters for both the Pasadena fully checkered grips and the TDE partially checkered grips to Ed. At one point, Harry borrowed back the grip masters for the TDE guns from Ed to make grips for the “B” model guns. They were stolen from Harry and Ed never got them back.

After Harry died the newly formed Galena operation moved from Irwindale to Sturgis, South Dakota. Larry Grossmann moved the Auto Mag inventory to Hesperia, California. He had a jig for drilling the holes in the frames and a rib profiling tool. Besides his Lectroetch machine there were not many unique Auto Mag factory tools left.

Marking Methods Inc., in Alhambra, California still makes electro-chemical marking equipment and the required stencils that were used by the factory. Bob Barbasiewicz used the old Pasadena Lectroetch machine to mark the North Hollywood guns and then it was thrown out. Ed O’Neil recovered it and sold it.

There were unique chamber, recoil rod and frame reamers used to make Auto Mags. The Pasadena #30 (retaining ring) installation tool was made by the factory and sold on a limited basis. Later a manufacturer was found who made a red anodized version of the tool that was sold by the factory and by Lee Jurras. The go-no-go gauges are kind of interesting as well as the aluminum grip masters used to create the silicon molds to cast the grips. The grip masters are very delicate as one wouldn’t want to flatten the tops of the checkers.

There were several brass patterns made for engraving barrels for presentation guns. They were four times larger than the eventual markings they would create. These patterns were used with a pantograph engraver to engrave markings onto the barrel instead of the production electro-etching. Bloss Engraving in Pasadena, California did the factory’s engraving. When they went out of business, Ed O’Neil bought the patterns from them.

AMT made a sight adjusting tool, in several colors, that was supposed to be included with the Harry Sanford Signature Series guns.

8) Scope Mounts

Because the Auto Mag is a short recoil operated gun, a scope mounted to the short recoiling barrel gets quite a beating. A bigger problem for the Auto Mag is just getting a scope mount that stays put. Many have tried and many have failed with the clamp-to-the-rib style mounts. Mounts that use screws to secure the mount to the rib eventually end up with broken screws.

Kent Lomont created the large scope mount that Lee Jurras used on his first five Custom Model 200’s. Kent’s mount was well secured to the barrel and had plenty of surface area to keep the scope from moving within the mount. The base was made of titanium and the rings were made of stainless steel.

Lee later used a custom mount made by Jim Herringshaw called the Maxi-Mount. Jim’s mount relies on two metal rings to prevent the mount from moving. The bottom of the ring sets in a milled out area in the rib and the top of the ring sets in a matching milled out area in the scope mount. Screws go through the center of the rings to hold everything together but don’t feel any stress during recoil. This aluminum mount has plenty of surface area to keep the scope from moving within the mount. Jim had one mount made that has six screw holes on top to hold the scope. The six hole mount was for mounting on a rib that still has the raised rear sight mounting area on the rear of the rib. Jim also made an eight hole mount that was to be used on barrels that didn’t have the rear sight mounting area on the rib.

The only other successful mount was the Willis scope mount. This frame mounted scope mount was ahead of its time. Made of aluminum by E. Clive Willis III, it was anodized in silver or gold. The gold faded to silver with time. This clever mount requires no alterations to the gun and recoil doesn’t harm the scope. Some say it is ugly.

The only scope available at the time that held up to the recoil was the Leupold M8-2X. Now there is also a Thompson Center Arms scope that has been successfully used on the Auto Mag.

9) Paperwork

This is probably the biggest area of Auto Mag collectables. Factory generated paperwork is just one of many one of many sources for Auto Mag related printed matter:

Brochures, price lists, advertising, manuals, warranty cards, ammo box stickers, gun case stickers, blueprints, interoffice memos, business cards, patents, publicity packages, photographs, receipts, letters of authentication, bankruptcy paperwork, reports, contracts, envelopes, stationary, club application forms, club membership cards, order forms, loading data, memo pads, autographs, etc., etc. .

Now, look for some of these same items from manufactures of ammunition, dies, holsters, gun cases, scope mounts, toys or from gun distributers.

Add to this magazines, books, comic books, newsletters and movie items.

The factory is best known for its Auto Mag brochures, advertising, loading data and the manual. Factory blueprints are exciting but people will always ask if they are original. Technically only the first pencil drawn drawing would be “The Original.” Copies, or copies of copies of these drawings are a close as many of us will get to these prints. Also there may be several revisions to any one print and there are associated ECO’s, engineering change orders, that go with each revision. Factory paperwork seems to be endless.

In 1969 a paperback book series started, titled “The Executioner,” featuring Mack Bolan. Mack eventually started using an Auto Mag that he named the Silver Belle, the Silver Lady or Big Thunder. By the early 70’s the cover of the paperbacks started using a drawing on the cover with Mack holding a reverse negative of the gun featured in the Aristocrat brochure. The series ended up with over 100 different books and some used elaborate Auto Mag paintings on the covers. In 1975 Major George C. Nonte, Jr. and Lee E. Jurras released a book titled Handgun Hunting. The Auto Mag was featured on several African hunts. In 1998 the author released a book titled Auto Mag the Pasadena Days. In 2004 Brian Maynard, the onetime AMT service manager, released a book titled Auto Mag Owner’s Reference Manual.

Lee Jurras generated quite a lot of paperwork as a gun distributer. His brochures including his eight page color brochure are quite well done. If you joined the “Club de Auto Mag Internationale, Inc.” you would receive twelve issues of “L. E. Jurras’ Auto Mag Newsletter.” You would also receive a membership card, a certificate suitable for framing and a club patch. There were fourteen newsletters from April 1974 to May of 1975. There was a fifteenth newsletter that was mailed out in January of 1977. Lee actually had a “Super Vel Newsletter” before the Auto Mag newsletter. There were five Super Vel newsletters from November 1973 to March of 1974. The Super Vel Newsletters contain several Auto Mag related items.

Auto Mag collector George Hebert published a four page newsletter titled “The Auto Mag Newsletter” in November of 1997.

The Warlord series of comic books featured an Auto Mag on the cover of several issues.

There was also an Executioner series of comic books. The first four comics would contain a complete story. Unfortunately only three were published before they went out of business.

10) Auto Mag Toys

Amt Pistol Serial Numbers

This is a favorite category of many collectors. The variety of technologies, sizes and colors makes this collectable almost as varied as collecting the real thing. The Japanese are truly the masters of the toy gun. The first time one enters a Japanese toy gun store is a memory not soon forgotten. Some are aged and you would swear they are 150 years old or a battlefield pick-up. Some are just models, and some fire a pellet or a soft dart. Some pellets are projected with a simple hammer strike on the pellet, some use a cap and some use a compressed Freon oxygen mixture that is held in the magazine. Some go bang with a cap and cycle a piece of brass (blowback) but have no projectile. Some are airsoft guns. There are also many beautiful Japanese model Auto Mags. They usually have to be assembled with glue from a large number of plastic parts. Most of the models don’t do anything. The artwork on many of the boxes is intriguing and could be a study by themselves.

MGC, Model Gun Company, is one of the largest toy gun stores in Japan and offers high end copies of many different guns. Of the high end Auto Mags they offered, one was silver, one was a matte silver, one was black, one was blued, one was made of clear plastic and one was black but the plastic was weighted to make the model gun as heavy as an original Auto Mag. MGC also made holsters and magazine loading tools for the Auto Mag.

As early as 1982 there were Auto Mag airsoft guns made with a 10.5” fully ribbed barrels. Interestingly, Kent Lomont made at least one .44AMP 10.5” fully ribbed barrel that is stunning.

After the movie Sudden Impact came out there were many toy “CLINT” Auto Mags made in Japan. They were 8.5” fully ribbed guns in a variety of cases and a variety of colors. There were some made of plastic and some made of metal. They were offered in black, silver or gold.

Probably the most poorly thought out toy is the Auto Mag flashlight. Imagine hearing a noise outside and using a flashlight shaped like an Auto Mag to investigate. It may end up being your last decision.

There is a toy squirt gun, toy cork guns, one that fires rubber bands, and one that fires a laser beam, has sound effects and scores with a reflective target.

11) Movies and TV

We all keep a sharp eye out for Auto Mags when guns come into play on the TV or in a movie. An old friend, David Heilman, loaned out his Pasadena Auto Mag to be used in the movie Scared to Death. When the gun was returned it had apparently been beat to death. The Sudden Impact gun was a blank firing gun made by the factory for the movie. It was serial number CLINT-2. CLINT-1 was a functioning gun that went to Clint Eastwood. Mr. Eastwood’s people would not allow the factory to make anymore CLINT serial numbered guns. In an episode of TJ Hooker, Captain Kirk uses the blank firing CLINT-2 gun to hold off the bad guys. In Beverly Hills Cop 2 the Auto Mag can barely be seen. Syd Stembridge made the prop guns for this movie and the author sold him some parts for them. Syd later said that most of the Auto Mag scenes were left on the cutting room floor. The movie Malone introduced a custom gun case for the Auto Mag that had not been seen before. The gun lies on its left side allowing for a better acquisition by the right handed shooter.

You could collect a copy of every movie; find movie posters, lobby cards, glossies, scripts, call sheets and the ticket stub from the movie house where you first saw it. Add advertising and review publications to this media based category and one could get really carried away.

Here are some spottings.

1) Scared To Death 1981

2) Sudden Impact 1983

3) T J Hooker TV episode 1982 – 1986

4) Miami Vice TV episode “Defiantly Miami” 1986

5) Beverly Hills Cop 2 1987

6) Malone 1987

7) The Hardway 1991

8) Destination Vegas 1995

9) Hackers 1995

10) The Intruder 1999

11) Battle Royale 2000

12) Patlabor 3 animation 2002

13) Grand Theft Auto IV Video Game

14) 25 to life Video Game

12) Jurras Accessories

Among other things, Lee E. Jurras has been an ammunition manufacturer, a custom gunsmith, an inventor, a writer, a publisher, a gun distributer, a gun broker, a marketing expert, a big game hunter and a locksmith. Lee offered replacement parts, ammunition, and a large number of accessories for the Auto Mag.

Some of the things that Lee Jurras offered were: laminated wood stocks, bone Micarta stocks, maroon linen Micarta stocks, shoulder holsters, shoulder stocks, belt holsters, clip pouches, black chromed rear sight blades, European style oil bottles, wrench sets with bone Micarta handles, wrench sets in a yellow plastic pouch, clip depressors, club marked Zippo lighters, part number 30 tools, Pasadena cartridge boxes, .357AMP taper crimp dies, a club windbreaker, a pen and pencil set, a key chain, a club patch, Gun-ho gun cases and the book Handgun Hunting. There was a yellow Jurras gun case sticker that sometimes the factory put on the black plastic factory case when they drop shipped a Jurras marked gun from the factory. Super Vel made up calendars, several bullet boards and a Super Vel ashtray.

13) Miscellaneous

This category encompasses some rather odd items that may seem to be only marginally related to the Auto Mag. The Irwindale factory cement parking lot tire bumper that had Harry spray painted on it would seem to be a stretch but one collector just had to have it. The AMT “no trespassing” sign off of the Irwindale factory’s fence was another got-to-have for a collector. Harry Sanford’s desk and other personal items have been snatched up by willing buyers.

Harry also made and patented the Auto-Scale digital powder scale and the Hungry Camper, which was a knife, fork and spoon combination that would cut your lip when used.

Kent Lomont sold a magazine belt clip and heavy leather Auto Mag barrel cases to be worn on the belt.

There are many articles of clothing that have the Auto Mag name. There were jackets, patches, hats and T-shirts to name a few items. Also to be worn are pins and a belt buckle.

Ransom International of Prescott, Arizona made grip inserts for the Auto Mag to be used with their gun rest.

The covers of the Executioner books, comic books and toy gun box covers that show an Auto Mag used a painting or drawing to create these covers. Many of these were destroyed but to own an original piece of this artwork is unique.